Осадочный резервуар

Осадочный резервуар

$2000-15000

Подробная информация о продукции

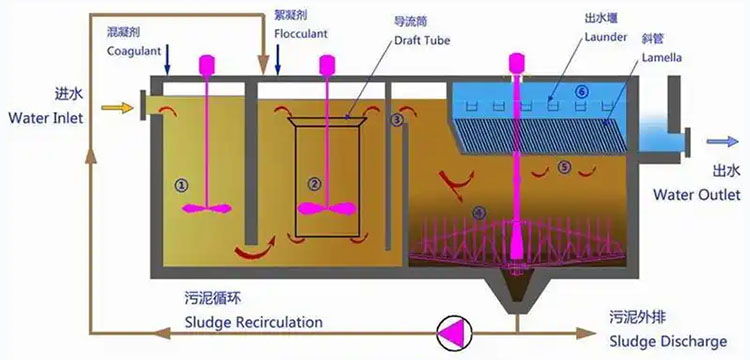

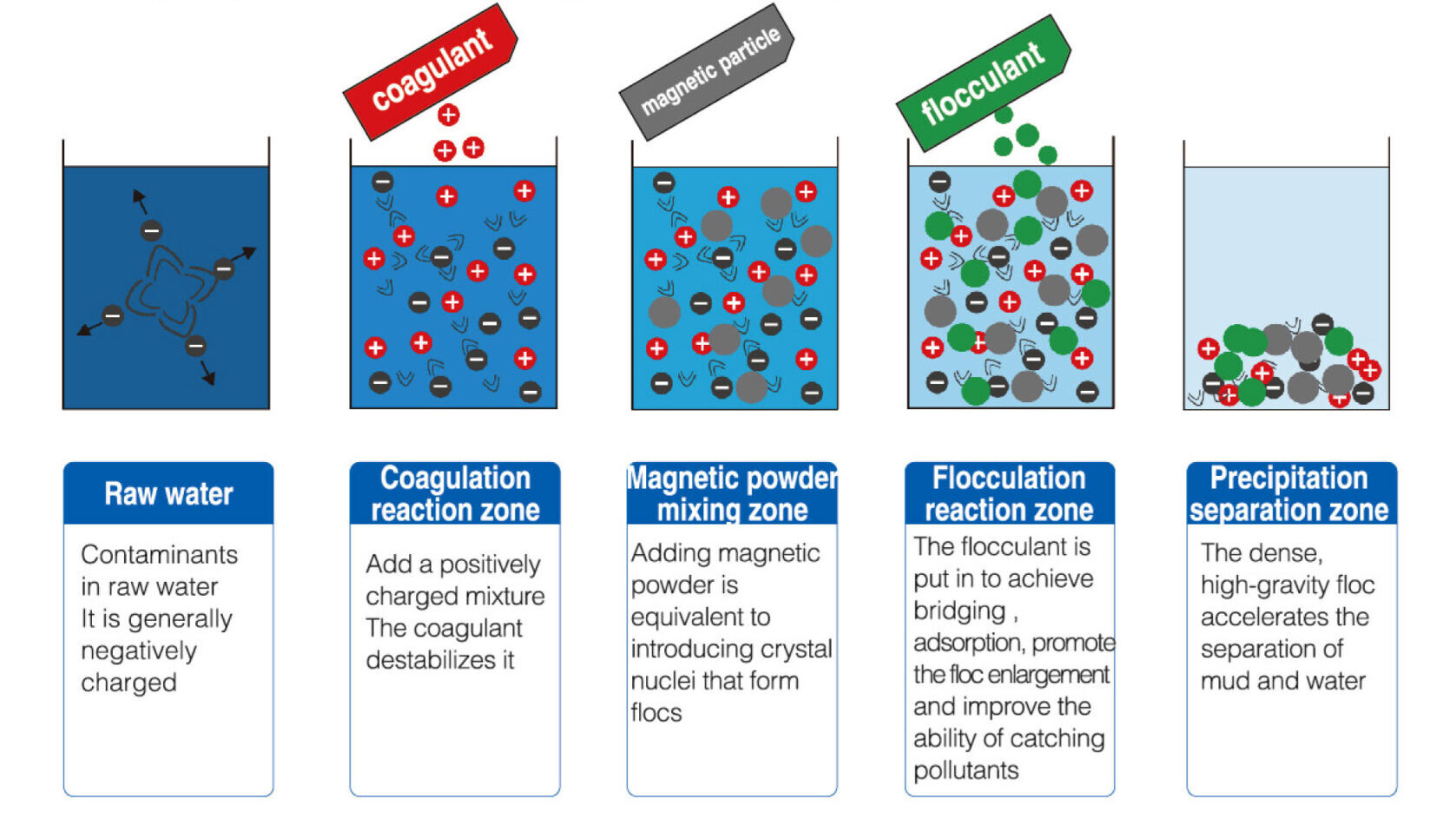

Overview: Magnetic coagulation sedimentation tank is an ultra-efficient precipitation deep water purification technology upgraded on the basis of high efficiency sedimentation tank process and its process flow chart is shown below. Introduce magnetic particles into the water purification process of efficient flocculation sedimentation tank, combine insoluble pollutants such as algae, tiny suspended matter, colloids, bacteria, etc. in the water with particle magnetic powder through flocculation, attraction adsorption, charge adsorption, bridging, net trapping,etc(magnetic powder specific gravity 5.2) forming a larger volume and density of magnetic floc strengthening the flocculation effect. it can capture the pollutants with smaller particle sizes making the flocs settle quickly and water purification etect excellent. The eftluent is clear and transparent. The sludge in the sedimentation tank is pumped back to the magnetic powder sludge separation system, and the magnetic powder is recycled and used, and the separated sludge is discharged into the sludge tank for dewatering treatment.

Advantage

1、Be able to effectively remove SS, algae, oil, bacteria, colloids and other non-soluble pollutants and caused turbidity,COD, chroma and odor (SS<3mg/L, turbidity <1.0NTU); Fe or AI coagulants can be used to remove phosphorus in depth at the same time (TP<0.05mg/L); Combined with pre-oxidation, iron, manganese and arsenic can be deeply removed. Cu, Cd, Hg, Pb, Cr, Zn, Mn, Ni and other heavy metal ions can be efficiently removed by adding Ca(OH)2 and organic sulfur. Adding pre-chemical precipitates such as Ca(OH)2 can soften the water(reduce hardness/alkalinity).

2、Small footprint, stable effluent, covering an area of about 1/8 of the traditional flocculation precipitation, short system residence time(<15~20 minutes).

3、The magnetic powder recovery rate is high (99.9%), and the magnetic powder loss rate is low.

4、Low operating costs, the use of micro magnetic flocculation technology, small dosage, and magnetic powder recycling rate is high, low operating costs.

5、Easy daily maintenance, high degree of automation, stable and reliable operation.

Add magnetic powder in the coagulation precipitation. The small size of the magnetic powderacts as a crystal nucleus, making it easier to form alum flowers. At the same time, it greatlyincreases the proportion of alum flowers and accelerates the precipitation rate. lt’s like cloudseeding to artificially increase the nucleus.The component of the magnetic particle added was FeSO4. The molecules were ordered to forma magnet. Fes04 molecules were disordered to form a maanetic particle, Maanetic powder itselfis not magnetic, but can be attracted to magnets.Magnetic powder has the characteristics of high density, stable strueture and recyclability, andits particles are about 100 microns.